The Longship CCS project is the first of its kind in the world, and the only CCS project under construction in Europe. The project consists of the two capture operators Heidelberg Materials (ETS sector) and Hafslund Oslo Celsio (non-ETS sector) and the transport and storage operator, Northern Lights. Being the first project of its kind presents challenges regarding laws and regulations. Regulations have not been adapted to this industry in Norway, the EU or through bilateral agreements.

Longship is facing regulatory complications because the project includes CO2 from ETS and non-ETS sectors. Additionally, liquid CO2 is transported using trucks and ships in this CCS chain, while current regulations have assumed transport is done via pipelines.

Responsibility for monitoring and reporting

The aim of CCS is to eliminate carbon emissions to the atmosphere in order to reduce global warming. For commercial operators in the chain, value for them is linked to the carbon that will be stored. It is therefore important to monitor the quantities of carbon being captured, and any quantities that leak out in the CCS chain.

When we talk about who is responsible for “CO2 in the chain”, we mean the responsibility for monitoring and reporting on the quantities of CO2 transferred and any potential leaks along the way. For Longship, the three industrial operators – Heidelberg Materials, Celsio, and Northern Lights – are responsible for monitoring and reporting to Norwegian authorities, but they are responsible for different parts of the chain. Norwegian authorities must then report on this in line with applicable international agreements.

Regulations for ETS sectors

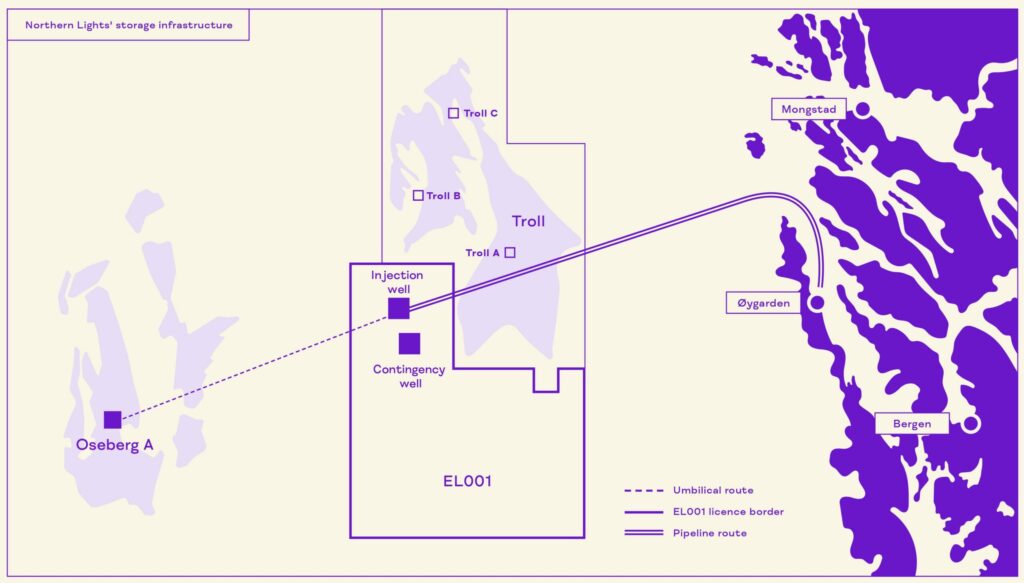

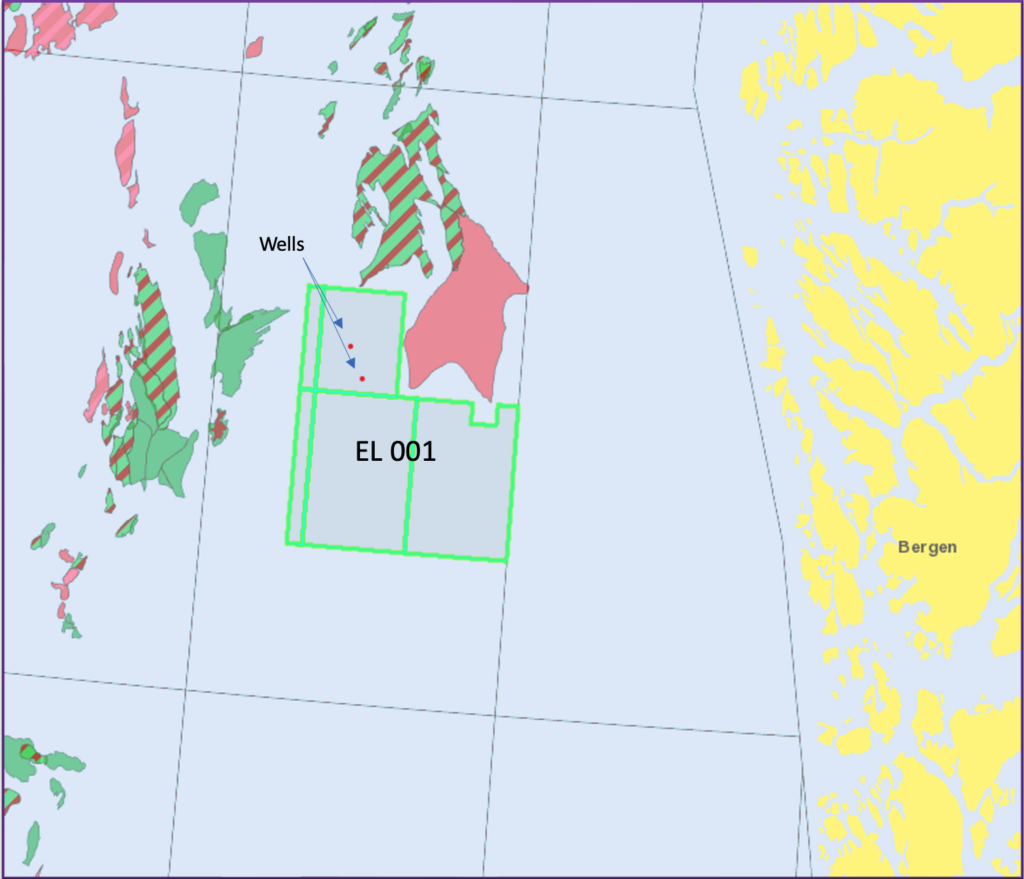

According to the Norwegian interpretation of the EU’s Monitoring and Reporting Regulations, carbon capture operators will be able to deduct CO2 from their emissions accounts once it has been transferred from the CO2 transport ship to the reception terminal in Øygarden, on the west coast of Norway. The European Commission has concurred with this interpretation of the law.

For the carbon capture operator, Heidelberg Materials, this means that it cannot deduct carbon dioxide from its emissions account before it has been transferred from the ship to the reception terminal and Northern Lights has issued a confirmation of the quantity of CO2 that was delivered. According to the EU’s ETS directive, Heidelberg Materials will not have deductions from its emissions approved for any leaks of CO2 during transport.

During negotiations with the Norwegian state, Heidelberg Materials made it clear that it was unacceptable to risk a financial loss due to leakage of CO2 from a ship that Heidelberg Materials did not operate itself. It was therefore included in the agreement that Northern Lights and the state will cover the costs in the event of CO2 leaks from the ship.

Regulations for non-ETS sectors

Hafslund Oslo Celsio is the other capture operator for Longship and will capture carbon from a waste incineration plant in the Oslo area. Celsio is not subject to the rules of the EU’s ETS directive because the plant is part of non-ETS sector.

The carbon captured by Celsio will be transported using trucks to a temporary storage site at the Port of Oslo. From there, it will be transferred over to the CO2 transport ship operated by Northern Lights. Neither the trucks nor the ships are currently regulated by the EU’s ETS directive.

Once the carbon captured by Celsio has arrived at the Northern Lights reception terminal in Øygarden, all the CO2 will be regulated by ETS regulations in the same was as for Heidelberg Materials.

The transport and storage operator

With the exception of the ship transport, all of Northern Lights’ activities (the reception terminal, the pipe trench, injection well and storage area) are subject to the EU’s ETS directive. It is clarified that Northern Lights is responsible for any leakages. In the event of leakages, the cost of these will be divided between Northern Lights and the state according to a separate agreement about cost sharing for the volumes in the Longship project.

Commercial customers

Alongside transporting and storing CO2 from the carbon capture operators Heidelberg Materials and Celsio, Northern Lights has further capacity. They have the option of entering into agreements for transport and storage with other operators. The party responsible for the CO2 being delivered to Northern Lights’ ships from customers in Norway and abroad will, in principle, be regulated in the same manner as for Heidelberg Materials and Celsio. Individual agreements must be signed if the carbon capture operator will not be responsible for the CO2 during the transport phase as this is not covered by the EU’s ETS directive. However, regulations here are under development. In a proposal from the European Commission, supported by the Council of the European Union and the European Parliament, it has been suggested that all transport for the purposes of carbon storage should be defined as ETS activities. The proposal has not yet been adopted.

Further complications arise when CO2 needs to be transported across borders. In addition to defining who is responsible on a commercial level, there is also a need to define who is responsible in the countries involved. At what point is the responsibility for a CO2 leak during transport transferred from one country to another? This question must be clarified and defined through, for example, bilateral agreements between the countries. This must therefore be in place before the start-up of any commercial CCS chain between a new customer and Northern Lights.

The EU system for emissions monitoring and reductions:

EU cooperation to reduce greenhouse gas emissions is formed of three pillars. All in all, these three pillars set the upper limit for greenhouse gas emissions. Norway is involved in all three pillars of the EU’s climate policy:

- The European Emissions Trading System (ETS) regulates emissions from manufacturing, energy and heat production, petroleum, and air travel through the ETS directive

- The Effort Sharing Regulation for non-ETS greenhouse gas emissions: This allocates each country a binding target to reduce emissions from transport, construction, agriculture, waste, and some types of emissions from the oil and gas industry and industrial manufacturing.

- The Land-Use, Land-Use Change and Forestry (LULUCF) Regulation: This regulation sets the rules for how to capture CO2 in the LULUCF sector. The regulations set an obligation that total greenhouse gas emissions from land-use and forestry must not exceed the captured amount (known as the “no-debit” rule).

This article is based on the report “Regulatory lessons learned from Longship”, which is based on the experiences gained from the Longship project.